Share this @internewscast.com

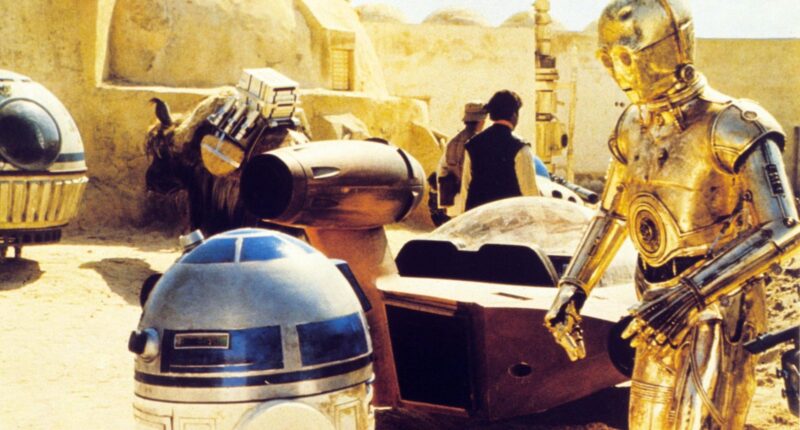

The depiction of robots has long been a staple in American pop culture, with their portrayal evolving significantly over the years. It all started with the iconic 1927 German film Metropolis, introducing audiences to one of the first human-like robots on screen. Over the decades, we’ve witnessed the transformation from the whimsical Tin Man to the formidable Gort, and from the beloved characters in Star Wars to the relentless machines in The Terminator and Transformers.

Today, we stand on the brink of turning yesterday’s science fiction into tomorrow’s tangible reality in both manufacturing and society at large. Humanoid robots are advancing rapidly, with experts predicting they will soon play a crucial role in our workforce. According to Goldman Sachs, the market for these robots could soar to $38 billion within a decade, while Fortune Business Insights suggests an even faster growth trajectory, reaching $66 billion by 2032.

While such advancements might seem daunting, they actually offer a promising solution to the severe global workforce shortages affecting various sectors. By 2030, a deficit of 85 to 100 million workers could cost the global economy $8.5 trillion in GDP, according to a Korn Ferry report. In the U.S., a looming shortfall of 1.9 million manufacturing workers by 2033 threatens the resurgence of American industry.

To bridge this gap, we need more workers, be they human or robotic. But how soon can we integrate humanoid robots into our factories? What will the collaboration between robots and humans look like? To explore these questions, I spoke with Shahad Samimi, CEO of Humanoid Global, a company investing in cutting-edge humanoid robotics, to gain insight into the technology’s potential.

Factories: On the Cusp of Change

In theory, factories are prime candidates for humanoid robots. Many manufacturing facilities already incorporate automation, with robotic arms and collaborative robots performing repetitive tasks. Humanoids, however, offer the potential to seamlessly integrate into human-oriented environments and processes without necessitating extensive factory modifications. “They’re designed for human settings,” explains Samimi. “They can handle tools, transport materials, and work alongside humans without requiring factories to undergo costly redesigns.”

But then there are the realities of manufacturing risk. If a service robot drops a tray on the way from kitchen to customer, costs are minimal. But a misstep in a factory could cause serious damage. So, for now, humanoids are cutting their teeth in mostly “low-level, easy tasks,” Samimi says, where the stakes are manageable. “We’re seeing companies we’ve invested in that are just purely focused on moving this box, this or that item, from A to B.”

At that level of involvement, a few companies are already wading in. Carmakers like Audi, BMW, and Mercedes-Benz, as well as Chinese EV-maker Zeekr, have piloted humanoids within operations. Amazon is using them in their warehouses.

The potential is much greater, of course. In theory, in the future, robots will be able to do just about any physical labor that a human can. But as many of us know, manufacturing isn’t known for its rapid pace of change. Plants are expensive, long-life assets, and managers don’t want to introduce variables that could compromise reliability or lead to regulatory scrutiny. Samimi suggests risk-scoring assessments and independent monitoring could eventually temper concerns. But in the meantime, even as factories are eager for new labor solutions, humanoids must meet the industry’s high standards for safety, consistency, and trust.

The Cost-Tied Tipping Point

Like other transformative technologies, humanoid robots won’t scale until the economics make sense. Today, price is still a big barrier to adoption. The cost sits around $50,000 per humanoid, Samimi says, a figure that puts the technology out of reach for most small- and medium-sized factories, particularly as task-specific automation can be cheaper and more reliable for smaller jobs.

But Samimi sees an inflection point on the horizon. “If we see it drop to anywhere between $5,000 and $10,000, we’ll see the sector shifting from automation to autonomy,” he predicts. At that price, robots start to look like practical additions to the workforce, investments in adaptable labor capacity that can be deployed in various ways as needs shift over time.

The timeline remains uncertain—Samimi would offer only that he expects some significant movement by 2030—but a downward cost curve would follow the path of other disruptive technologies, from industrial sensors to solar paneling. When prices do come down and leading plants prove out the return on investment, humanoids could reach a tipping point that cascades across the country.

The Blended Workforce Of The Future

American manufacturing’s resilience depends on how we embrace new technologies to bring the best out of our human workers. The next era of automation isn’t about replacing all manufacturing workers—it’s about combining their strengths with machines. The workforce of the future, then, will treat labor as a hybrid of human and machine capacity. In the shorter-term, exoskeletons could be deployed as a first step—granting human factory workers “superpowers,” Samimi says, allowing them to lift heavier and operate with greater precision.

Humanoid robots won’t transform manufacturing overnight—the costs and risks still associated with the technology means adoption will be measured, and uneven, for the foreseeable future. But the direction is clear: humanoids and other forms of augmentation, like robotic exoskeletons, could help close critical labor gaps and boost productivity. And the factories that experiment and keep tabs on the development of humanoid capabilities will be better positioned to compete in a world where the lines blur between human and machine work.